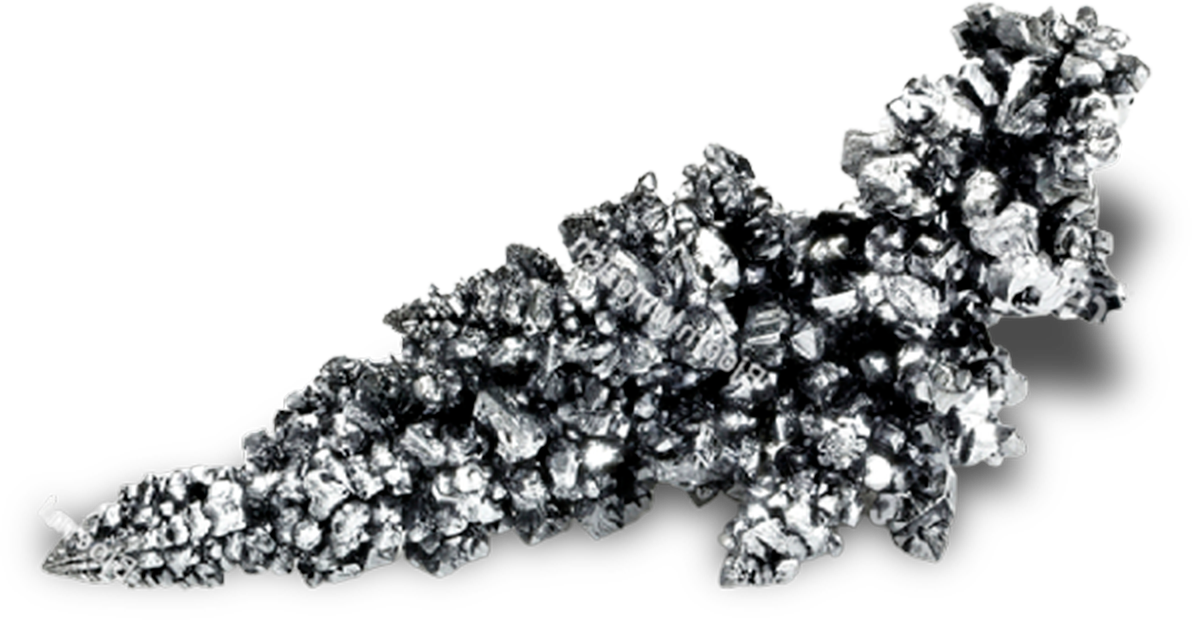

Vanadium

Our

Products

Products

BlackRock’s vanadium production is designed to be world-class in terms of purity and GHG emissions. We will emit 60% less GHG than our peers in the industry.

BlackRock Metals expects to produce over 35,000 tonnes per year of vanadium rich feedstock, representing more than 5% of the total global vanadium production. We will produce the only primary sourced vanadium in North America and the BlackRock Project plays a key role in the Canadian and American critical minerals strategies.

BlackRock Metals expects to produce over 35,000 tonnes per year of vanadium rich feedstock, representing more than 5% of the total global vanadium production. We will produce the only primary sourced vanadium in North America and the BlackRock Project plays a key role in the Canadian and American critical minerals strategies.

Our vanadium product is an important ingredient for high strength steel production at a time when the steel and foundry industries strive to produce stronger and lighter components for automotive, aerospace and other structural applications. This helps the industry use less energy and fewer raw materials leading to lower GHG emissions.

To illustrate the power of BlackRock Metal’s vanadium, if our annual production were to be used to produce ferrovanadium to alloy and strengthen construction rebar, over 26 million tonnes of GHG emission could be avoided annually. In the alternative energy industry, vanadium is used in Vanadium Redox Flow Batteries which store energy and enable grid-level renewable power generation such as wind and solar to reach its full potential and reduce its overall cost.

Application / Industries

Jet Engines

Vehicles

Vanadium Batteries

Construction of Buildings

High Purity Iron

Our

Products

Products

BlackRock Metals expects to produce over 500,000 tonnes per year of ultra clean nodular iron and high purity pig iron products for the high-grade steel and foundry industries. This would create over 21 million tonnes of iron feedstocks over the BlackRock Project’s many decades of operation.

Our iron products are designed to be world-class in quality. They have higher purity, lack detrimental residual metals, and create high value co-products and the lowest GHG emissions in the global iron and steel industry.

Our iron products are designed to be world-class in quality. They have higher purity, lack detrimental residual metals, and create high value co-products and the lowest GHG emissions in the global iron and steel industry.

BlackRock Metals has designed a state-of-the-art, clean technology facility to supply the modern steel industry as it decarburizes. The global steel industry is currently de-commissioning coal-based operations and is moving to cleaner modern electric furnaces. As the steel industry goes electric, the main ingredient for steel production becomes scrap metal, direct reduced iron (DRI), and pig iron. Accordingly, the industry will utilize BlackRock Metal’s ultra-low GHG iron feedstocks to dilute contaminants in the scrap metal and to meet ever lower lifecycle GHG emissions levels.

BlackRock Metal’s technology converts clean natural gas into hydrogen which is used to refine our high purity iron products. Also, this cutting-edge process is designed to replace natural gas with the direct injection of green hydrogen as it becomes commercially available in Quebec to further reduce the GHG footprint. BRM can also implement CO2 capture to eliminate emissions. Finally, our team is focused on identifying and implementing the best-in-class clean technologies to maintain a leading position as the lowest GHG emitter in the global industry.

Application / Industries

Wind Turbines

Airplanes aerospace

Compression tanks

Medical Implants

Titanium

Our

Products

Products

BlackRock Metals expects to produce 120,000 tonnes of titanium rich slag annually. This product is used to produce high purity TiO2 for use in the pigment, paint and coating industry which is continuously striving for longer lasting coatings for industrial applications. Titanium slag is also used for downstream production of titanium metal.

Our annual titanium production will represent the second largest source of primary titanium in North America and about 15% of total Canadian production. BlackRock’s titanium production further solidifies its position as a key component of both the Canadian and American critical minerals strategies.

Produced from the same process flow as our iron and vanadium, our titanium production is uniquely clean and decarbonized in emitting less than 50% of the average GHG emissions of all other titanium slag feedstocks produced globally.

Application / Industries

Cosmetics and food

Paint and coating

1080, Côte du Beaver Hall Suite 1606, Montreal

(514) 316-7281

(514) 316-7281

Legal - Use of privacy © BlackRock Metals 2021 - All rights reserved.